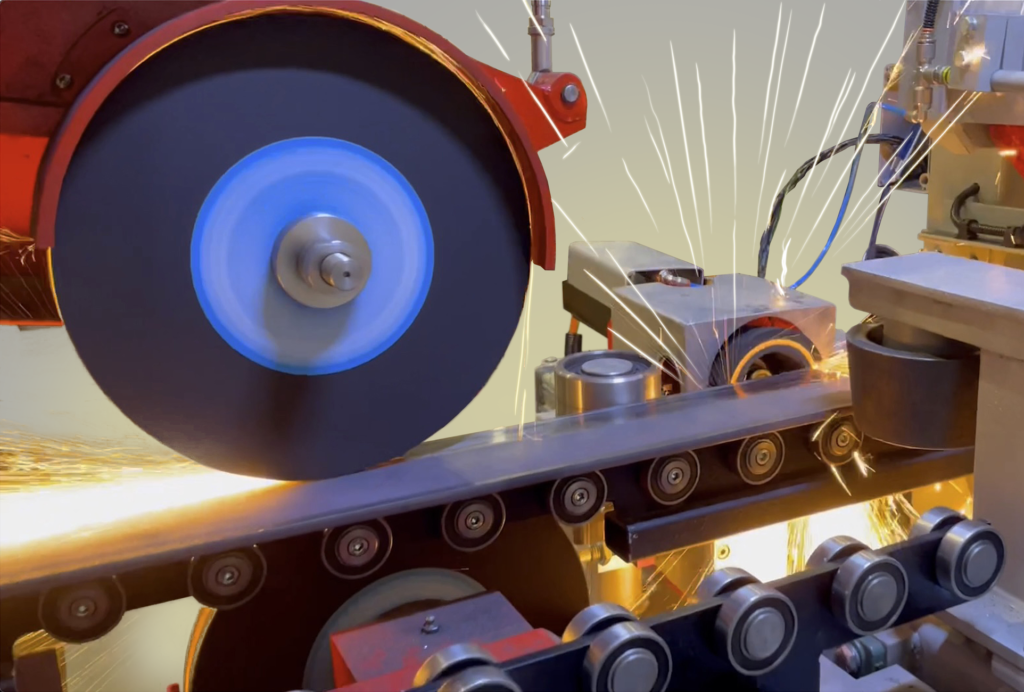

Products / Web grinding / Plate preparation lines

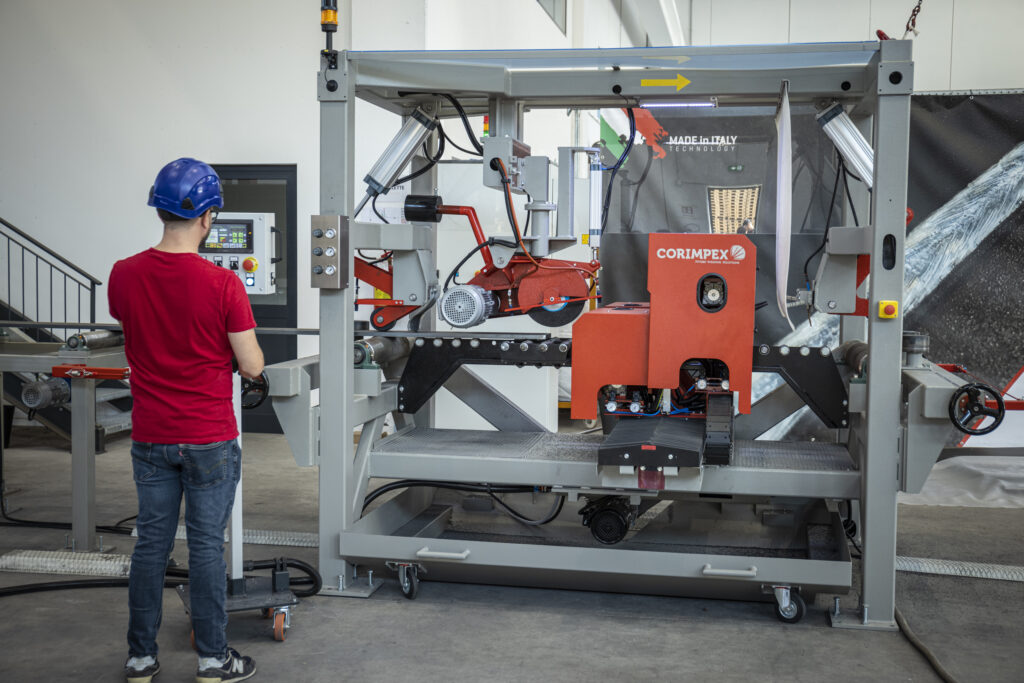

WFTB – Web Front Top Bottom

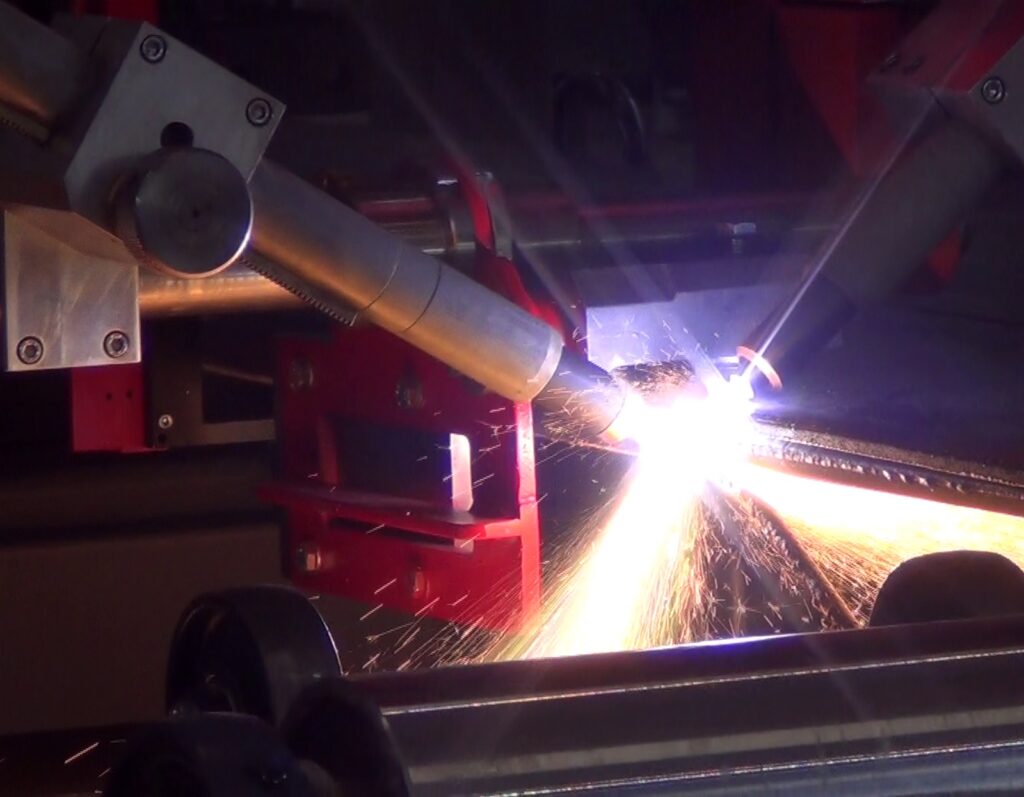

The WFTB machine, designed for webs and flanges grinding, allows to get a better cleaning in the area where the welding cord will be made, optimizing the entire welding process.